preventative & curative concrete

buildup removal

DrumJet-HP

Robotic concrete build-up removal system for concrete mixertrucks to remove sticked concrete, mortar and hardened, buildup from the mixerdrum blades and drumwall.

The DrumJet-HP system is a semi-automatic high-pressure concrete removal system, operated by a certified operator. The system replaces human entry for the manual concrete removal job with jackhammer in this named confined space.

European DrumJet-HP model G1 in operation, watch the small footprint

the DrumJet G3

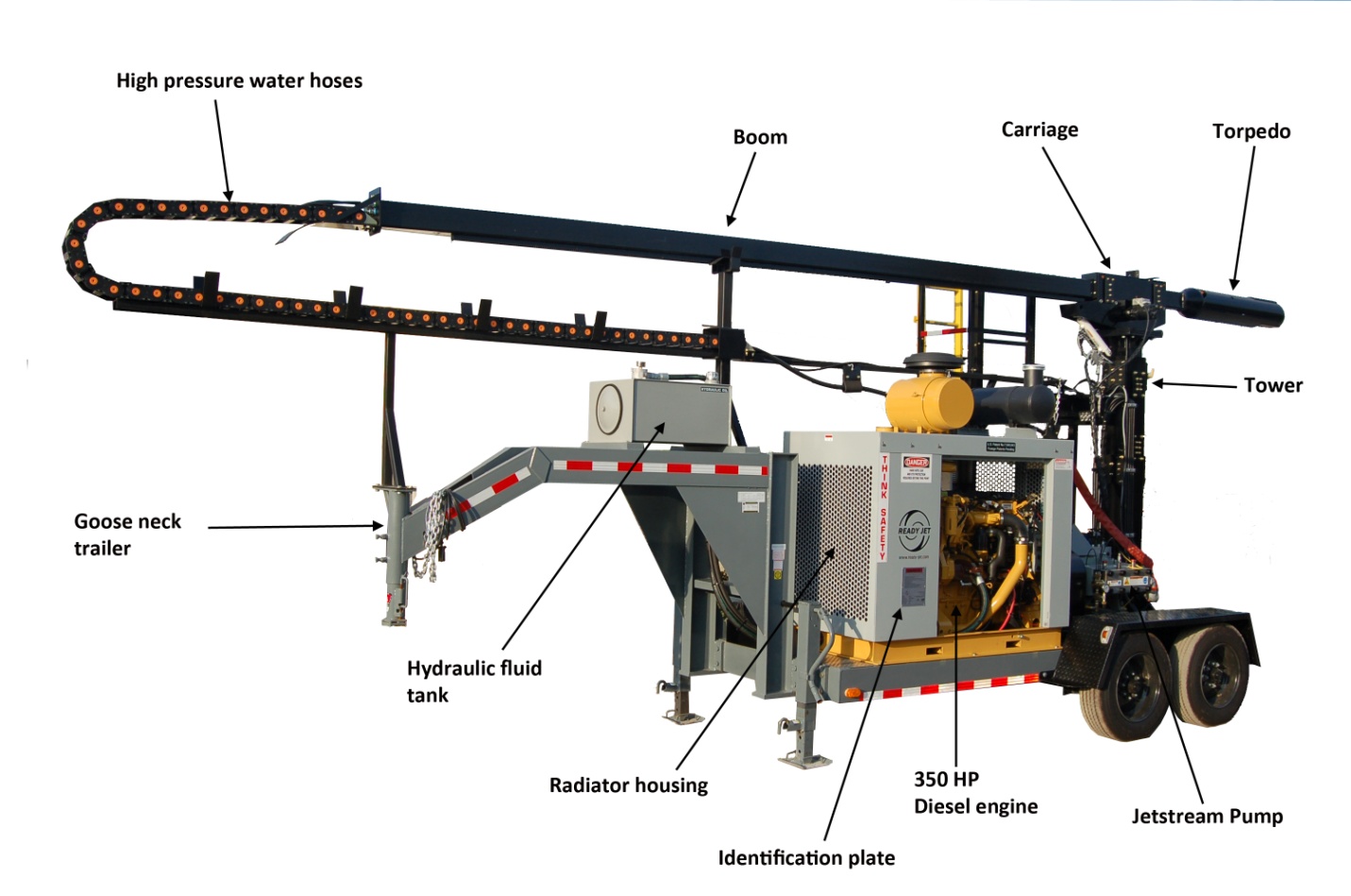

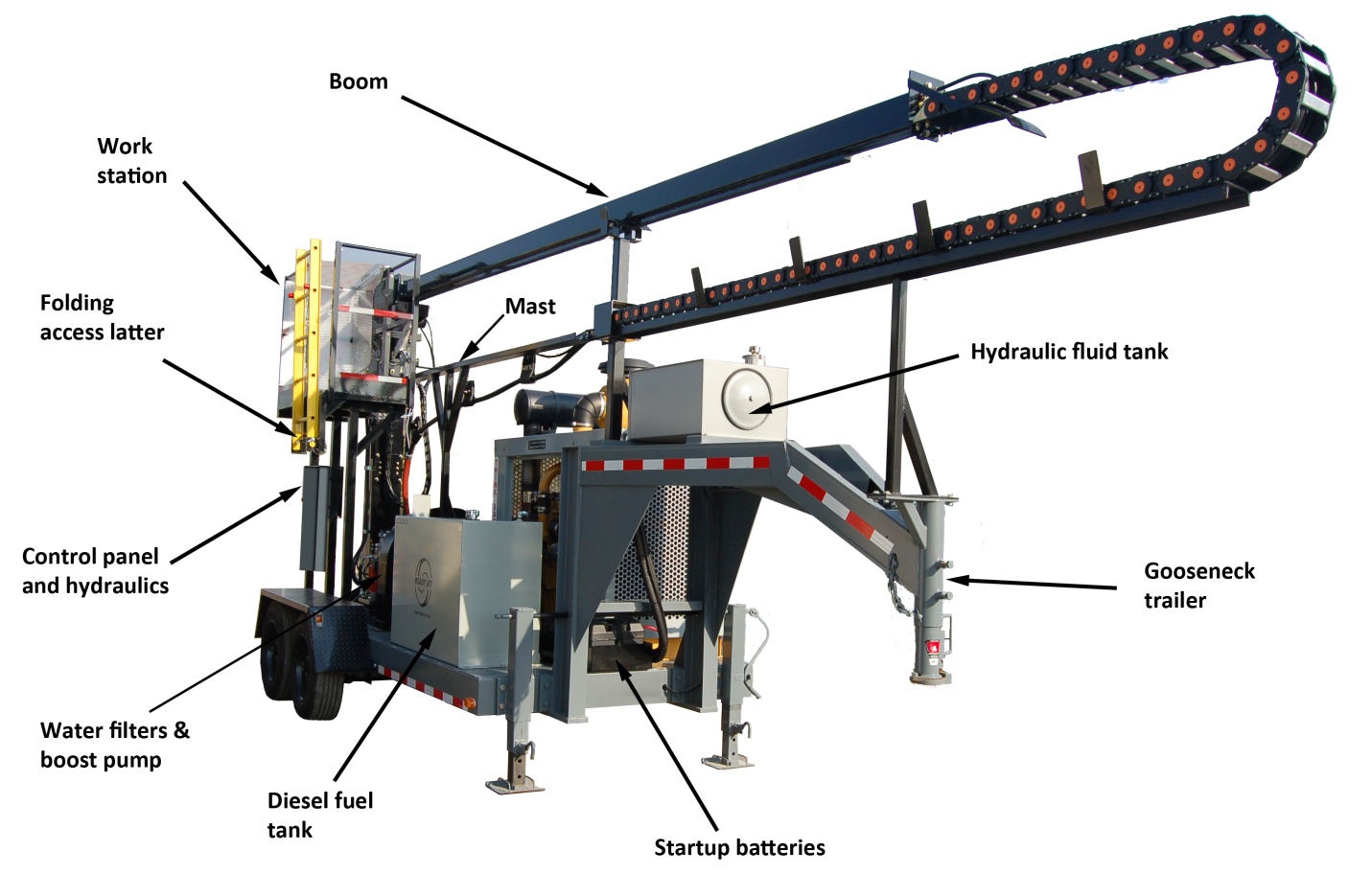

| MAIN ENGINE | Stage5, 350 HP, Diesel |

| HIGH PRESSURE PUMP | Jetstream 4220 |

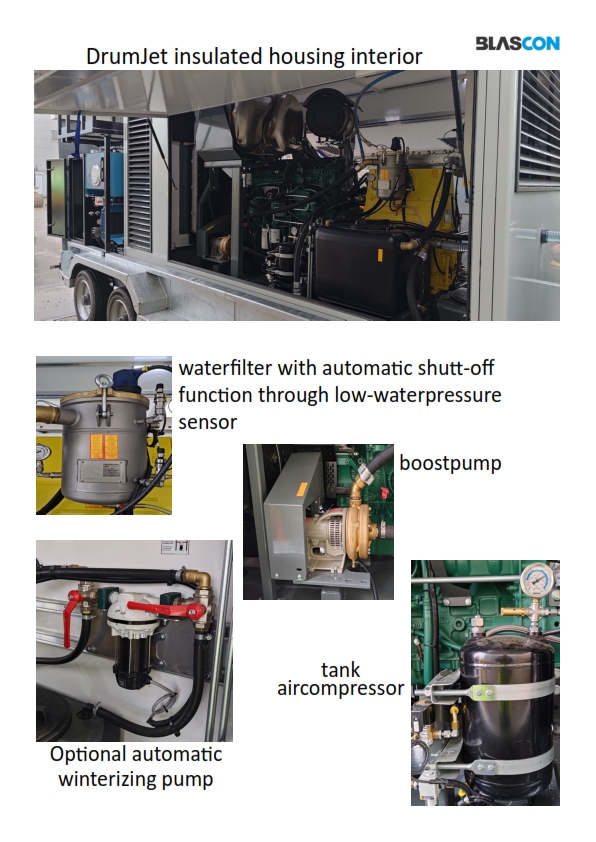

| BOOST PUMP | ACE FMC HYD-202 |

| CLUTCH |

Logan LC 314 |

| HP HOSES | 1400 Bar |

| HYDRAULIC MANIFOLD | SUN Hydraulics customized |

| FILTERS & HOUSING | FSI X-100 25&5 micron |

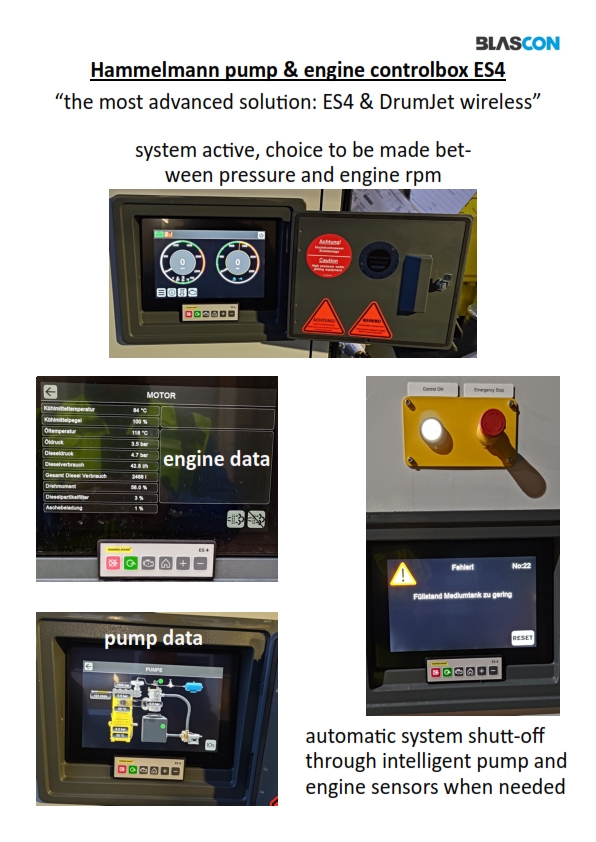

| REMOTE CONTROL | Scanreco customized |

| CONTROL PANEL | Wachendorf OPUS A3 |

History

Main goal for development of the DrumJet-HP is to prevent people entering the confined space of the mixerdrum. The system is developed as a curative method for robotic concrete buildup removal. The first generation DrumJet-HP machines are relay steered, actuating solenoid direct acting valves for hydraulic machine functions. The system is operated through a wireless remote control offering the operator to stay safe during operations.

Present, 2025

While the first generation DrumJet-HP was developed as a curative method, the third generation DrumJet-HP was a PLC steered machine. the DrumJet-HP G3 was in theory also offering more operator friendly solutions because of the PLC steering. The PLC steering actuates proportional valves and direct acting valves for all DrumJet-HP functions. All functions of the machine could be operated from the wireless remote controll which is equipped with a screen for easy function checks. The 2020 G3 machines were equipped with diesel engines complying with the latest exhaust requirements Tier4 Final (US) / Stage5 (Europe). Nevertheless 2025, the latest “DrumJet-HP model 2025” has made its entry into the market. The best and most robust system that has been developed for robotic mixerdrum concrete buildup removal until today.

DJet-HP 2025 BUILDUP PREVENTION & REMOVAL FEATURES

Adjustable features of the “DrumJet-HP 2025” result in buildup prevention & buildup removal usability

| INTERVAL |

| CLEANING ART |

| TIME (9m3 drum) |

| OSCILLATION |

| WATERPRESSURE |

| Feature 1 |

| Daily |

| prevention |

| 15 minutes |

| 35° range |

| 250 Bar |

| Feature 2 |

| Weekly |

| prevention |

| 25 minutes |

| 60° range |

| 500 Bar |

| Feature 3 |

| Monthly |

| removal |

| 35 minutes |

| 90° range |

| 900 Bar |

| Feature 4 |

| Yearly |

| removal |

| 70 minutes |

| 130° range |

| 1600/1800 Bar |

Highlights

Safety

Robotic concrete removal from confined space of mixerdrum preventing human entry

Automatic

semi-automatic system operated through wireless remote controll

Quick

Quick removal process,

Average removal time 45-70 minutes

Certified Operater

Certified DrumJet operator needed for the DrumJet-HP system.

wireless robotic concrete drum buildup washout & removal

Blascon NL Office

Stationsstraat 5A

NL – 7573 AT Oldenzaal

Phone: +31 625 307 807

Email: info@blascon.com

Blascon NL Delivery

Schelmaatstraat 21

7575 BC Oldenzaal

Blascon Deutschland

Twentestrasse 2

D – 48527 Nordhorn

Telefon: +49 1520 6273 901

Email: info@blascon.com