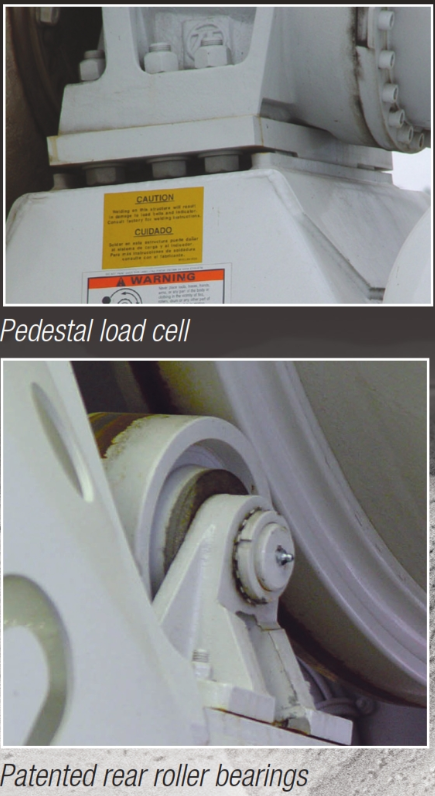

concrete truck patented mixer drum 3-point scales

LoadMan

Loadman scale is a 3-point real-time mixer drum weighing system that constantly indicates the weight of the drum. So with an empty drum only the weight of the drum. In the case of a mixer drum loaded with concrete, the weight of the drum and the load.

MEASURING LOAD & DISCHARGE VOLUME Extremely precise to measure the load but also the amount of concrete discharged. Easy with partial loads. Also easy with return loads and possible additional loading.

Supporting the work of:

– Driver of a mixertruck

– Concrete batcher

– Logistics and fleet management

IDENTIFY

precise volume & weight of:

– loaded fresh concrete

– concrete delivered by partial discharge

– carry-back concrete

– concrete buildup

– no credit invoices “delivered volumes”

– reuse of precise known “carry-back concrete” volume

– “wear & tear” diminished

– no fines for overloading

PREVENT:

– “overload”

– “delivered volume” issues with customers – concrete residue buildup forming

– wear & tear” while buildup monitored

The Challenge

Being able to track loads by weight in real time and determine the exact amount of concrete loaded, delivered and returned, as well as the location of the mixer truck in real time. The quantity of caked residual concrete is easy and constant to determine.

The Solution

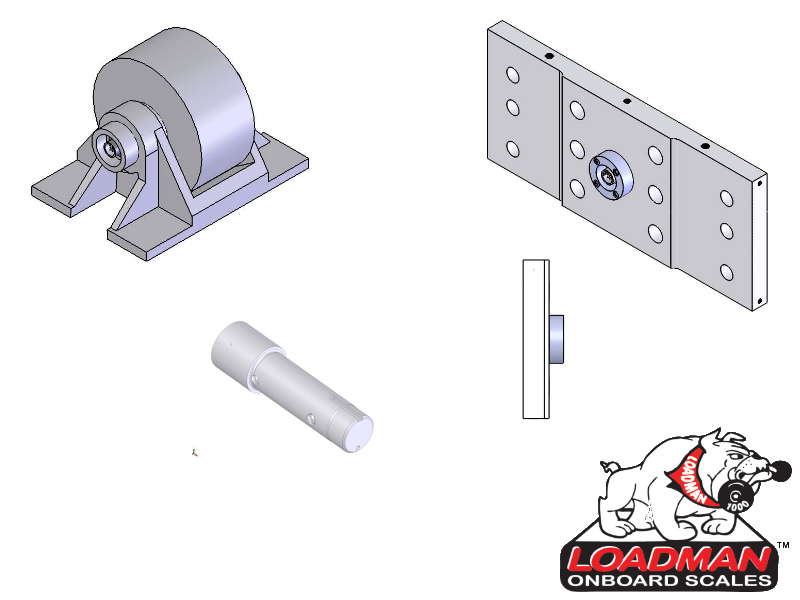

LoadMan® built-in weighing scale for concrete mixer drums that only weighs the weight of the drum and the weight of the drum with contents. The quantity of caked residual concrete is therefore also easy to determine at any time.

The Result

Loadman 3-point weighing system indicates in real time the exact quantity of loaded, delivered, returned concrete mortar. Because the quantity of caked residual concrete can be determined constantly, overloading can be prevented at all times.

Features

At the end of the day it’s all about the optimal ratio between delivered concrete volumes and costs. The LoadMan weighing scale delivers superior performance, allowing the mixertruck and load to be monitored for weight in real time. Data that can be read remotely in real time include: loaded volumes, delivered volumes, trip distances, number of trips, mixer truck location, driver times and other critical information.

Digital

Technology

Data can be read remotely by the driver as well as by the batcher and fleet manager. Digital possibilities such as mobile internet, wifi and bluetooth can be used for this purpose.

Patented Digital Encoder

Designed for superior temperature stability from -20° F to +140° F. Immune to moisture and EMI problems associated with analog systems.

Load Management Software

Storage of real-time data and reports with delivery history enable timely and profitable and/or cost-saving business decisions

profitable real-time drum / agitator weight monitoring

Blascon NL Office

Stationsstraat 5A

NL – 7573 AT Oldenzaal

Phone: +31 625 307 807

Email: info@blascon.com

Blascon NL Delivery

Schelmaatstraat 21

7575 BC Oldenzaal

Blascon Deutschland

Twentestrasse 2

D – 48527 Nordhorn

Telefon: +49 1520 6273 901

Email: info@blascon.com